This is a model of a penny I created using a Image2Surface script I wrote for Autodesk Fusion 360. With the script I was able to import a heightmap image of a penny and generate a mesh. I wanted to mill the model so I then converted the mesh to a t-spline surface. Fusion 360 doesn’t yet support milling meshes.

Once I had the t-spline, I created a block body for a base and then placed the t-spline atop that.

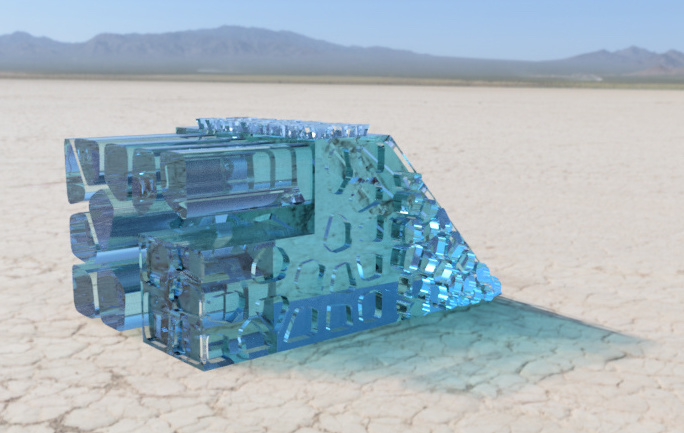

With the design done I then moved into the CAM environment and began setting up the tools and operations. This turned out to be a very easy setup with only 3 operations:

- 2D Face

- 3D Adaptive Clearing

- 3D Morphed Spiral

The material was a scrap 4″x4″ piece of 6061 aluminum.

Total run time for milling was around 50 minutes at very safe novice feeds and speeds. That means I spent 50 minutes making half a cent! 😉

Cheers!

p.s. You may find the script on my Github site: https://github.com/hanskellner/Fusion360Image2Surface

Leave a Reply